Fiber optical cables are advanced transmission media that use light signals to carry data over long distances with minimal loss. They have revolutionized telecommunications, internet networks, and data centers by providing high bandwidth, low latency, and resistance to electromagnetic interference.

Choosing the right fiber optic cable requires understanding its structure, types, performance characteristics, and installation requirements. This guide explores the factors and considerations that ensure optimal performance and long-term reliability.

Core Structure of Fiber Optical Cables

A fiber optic cable consists of several layers designed to protect the delicate glass fibers while enabling efficient light transmission:

- Core: The central glass or plastic fiber that carries light signals. Core diameter affects bandwidth and signal dispersion.

- Cladding: Surrounds the core and reflects light back into it, ensuring total internal reflection.

- Buffer Coating: Protective layer around the cladding that prevents physical damage and moisture penetration.

- Strength Members: Materials such as aramid yarn or fiberglass rods that add tensile strength and reduce strain.

- Outer Jacket: Protective covering against environmental factors, abrasion, and UV exposure.

Types of Fiber Optical Cables

Fiber optic cables are primarily categorized by the type of light propagation and core size. The main types include:

Single-Mode Fiber (SMF)

Single-mode fiber has a small core diameter, typically 8–10 µm, allowing only one mode of light to propagate. This minimizes modal dispersion and enables long-distance, high-speed transmission, making it ideal for telecom networks, metro, and long-haul applications.

Multi-Mode Fiber (MMF)

Multi-mode fiber has a larger core, typically 50–62.5 µm, allowing multiple light modes to propagate simultaneously. It is suitable for shorter distances, such as data centers, LAN networks, and enterprise applications. Multi-mode fibers are easier to install and cost-effective but have higher modal dispersion than single-mode fibers.

Indoor vs. Outdoor Fiber Cables

Fiber cables are also classified based on their installation environment:

- Indoor Cables: Lightweight, flexible, and fire-resistant. Often used in buildings, data centers, and telecom rooms.

- Outdoor Cables: Armored and UV-resistant to withstand harsh environmental conditions, including moisture, temperature variations, and mechanical stress.

Fiber Cable Configurations and Jacket Types

The jacket and structure of a fiber optic cable determine its mechanical protection and application suitability:

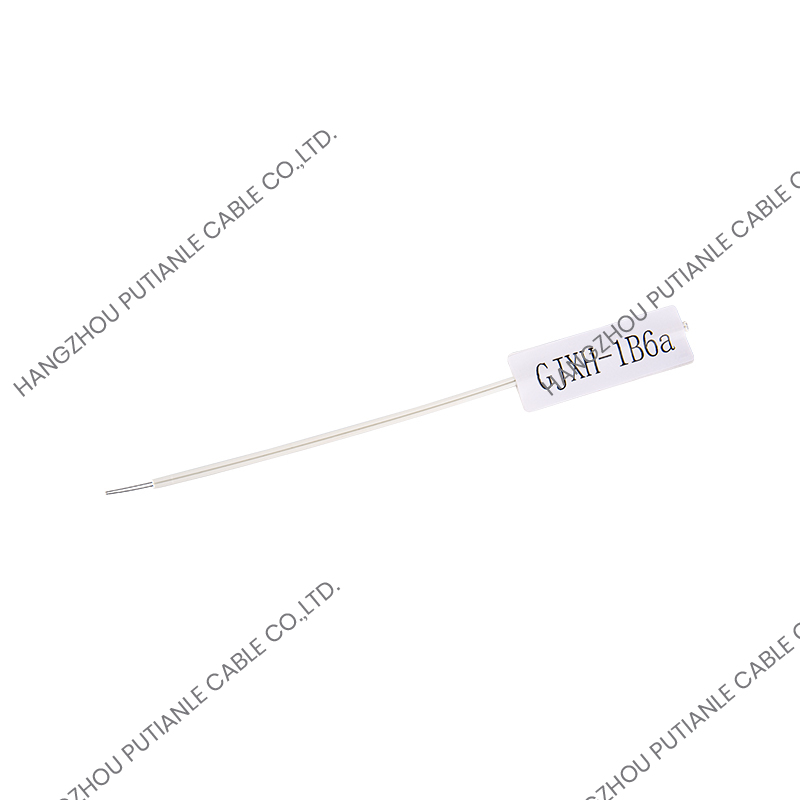

- Tight-Buffered: Fiber is coated directly with a protective buffer. Suitable for indoor installations and patch cords.

- Loose-Tube: Fibers are housed in a protective tube filled with gel or water-blocking material. Suitable for outdoor and long-distance installations.

- Armored Cable: Includes metallic or non-metallic armor for extra protection against rodents, crushing, and external mechanical stress.

- Plenum-Rated Jacket: Low-smoke, fire-resistant material for safe indoor use in air-handling spaces.

Factors to Consider When Choosing Fiber Optical Cable

Choosing the correct fiber optic cable involves evaluating multiple factors to ensure performance, reliability, and cost-efficiency:

- Distance and Bandwidth Requirements: Single-mode for long-distance high-speed; multi-mode for shorter distances.

- Installation Environment: Indoor, outdoor, aerial, underground, or direct burial.

- Mechanical Protection: Armor or loose-tube designs for harsh environments.

- Connector Compatibility: Ensure cable core and fiber type match connector types.

- Standards Compliance: Adhere to ITU, ANSI/TIA, ISO, and IEC standards for reliability.

Performance Parameters and Testing

Fiber optic cables must meet strict performance standards to ensure minimal signal loss, low attenuation, and high bandwidth:

- Attenuation: Signal loss over distance, measured in dB/km. Single-mode fibers have lower attenuation than multi-mode.

- Dispersion: Spreading of light pulses that affects bandwidth. Single-mode fibers reduce modal dispersion.

- Numerical Aperture (NA): Indicates light-gathering ability, affecting coupling efficiency.

- Tensile Strength: Determines how much pulling force a cable can withstand during installation.

Applications of Fiber Optical Cables

Fiber optic cables are widely used in various industries due to their high-speed, high-capacity, and interference-free transmission:

- Telecommunications: Long-distance, high-bandwidth data and voice transmission.

- Data Centers: High-speed connectivity for servers and storage systems.

- Enterprise Networks: LAN, MAN, and campus networks requiring reliable communication.

- Medical Applications: Imaging systems, endoscopy, and surgical instrumentation.

- Industrial and Military: Sensor networks, automation systems, and secure communication.

Conclusion: Choosing the Right Fiber Optical Cable

Selecting the proper fiber optic cable is essential for system reliability, performance, and future scalability. By considering factors such as fiber type, core structure, installation environment, mechanical protection, and industry standards, users can ensure their network meets performance requirements while minimizing maintenance and operational costs.

Investing in high-quality fiber optical cables not only improves data transmission speeds and network efficiency but also provides long-term durability in both indoor and outdoor environments.

中文简体

中文简体 English

English Español

Español